Integrated Study of Nanopowder Synthesis and Pollutant Control using Electrically-Assisted Combustion

Sponsor: NSF

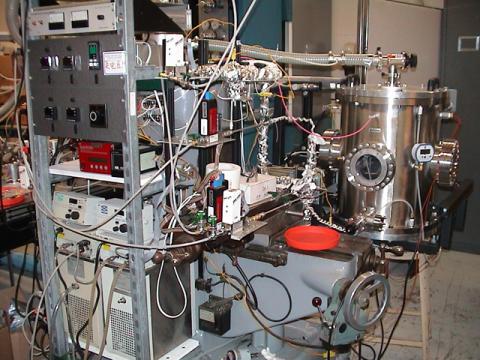

Among the processes that have been demonstrated for flame synthesis of nanopowders, the approach of applying electric fields is one of the most promising in terms of precise control of primary particle size, crystallinity, and aggregate size. Similarly, the same advantages hold for the control of particulate emissions from combustion systems used for power generation and incineration. The objective of the work is to increase fundamental understanding of the mechanisms of particle formation, growth, and aggregation in combustion systems subjected to external electric fields and utilization of that understanding to define process conditions that enable both 1) high-rate deposition of non-agglomerated nanopowders and 2) control of pollutant particulate emissions. The ceramic nanopowders investigated are SiO2, TiO2, Al2O3 and ZrO2, using high-volatility precursors. The use of multiple precursors to produce doped, coated, and mixed nanocrystalline nanoparticle microstructures are also studied. The pollutant particulates investigated are soot and particulates containing toxic metals, such as Pb and Cr.

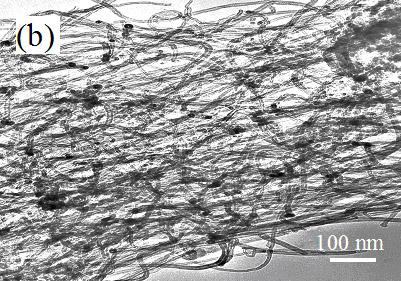

Catalytic Flame Synthesis of Carbon Nanotubes

Sponsor: NSF

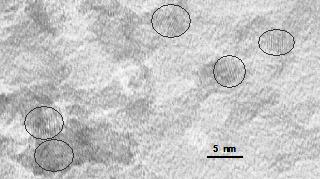

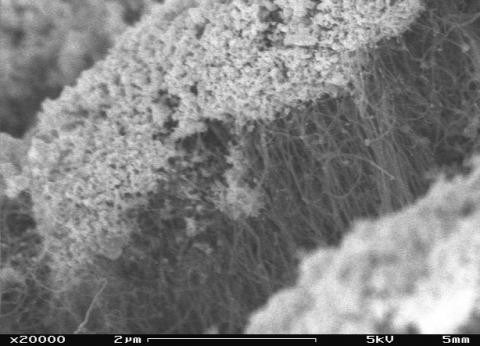

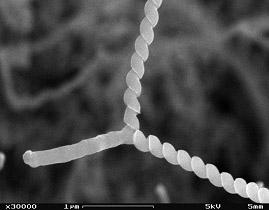

Carbon nanotubes (CNTs) are synthesized utilizing novel, electrically-enhanced, flame-based, catalytic methods. In utilizing combustion, a portion of the hydrocarbon gas provides the elevated temperatures required, with the remaining fuel serving as the hydrocarbon reagent, thereby constituting an efficient source of energy and hydrocarbon reactant. Strategically-chosen, quasi-one-dimensional flow geometries are employed to allow for precise experimental probing and deduction of fundamental controlling mechanisms, including the extraction of detailed chemical kinetics, which are difficult to realize in most of the other current methods of synthesis where conditions are often too chaotic to deduce any meaningful relationship with growth models. As such, the program integrates synthesis, in-situ laser-based diagnosis (of the gas and surface phases), and subsequent state-of-the-art materials characterization of CNTs to optimize CNT growth at high rates with prescribed characteristics (e.g. single- or multi-walled, diameter, helicity). Such a paradigm allows not only for detailed fundamental study of the mechanisms involved in CNT formation and growth but also for the active control of those basic processes, so that CNTs with tailored physical properties can be produced in large quantities with high purity.

Laser Diagnostics for Gas-Phase Synthesis of Nanostructured Materials

Sponsor: NSF

An injection-seeded Nd:YAG laser, dye laser, 500mm imaging spectrometer, 250mm monochromator, ICCD camera, CCD camera, PMTs, digital oscilloscopes, external cavity diode lasers, and various supporting optics and instruments enable the utilization of in-situ laser-based diagnostics to characterize gas-phase flow fields. We use Raman spectroscopy to measure the temperature and concentrations of major species (e.g. N2, O2, H2O, H2, C2H2); laser-induced fluorescence to measure the relative concentrations of important radical species (e.g. H, OH, NO), as well as, gas-phase precursors (e.g. PAHs and C2s); laser-induced incandescence to measure the relative concentrations of particles such as soot; laser-induced breakdown spectroscopy to measure the elemental make-up of aerosol particles; laser absorption spectroscopy to measure selected species; and laser doppler velocimetry to determine axial velocity distributions.

High Rate Processes for Nanoparticle Separation

Sponsor: Nano Engineered Innovation Corp., Army SBIR Phase II

The objective of this project is to develop a nanoparticle separation tool that eliminates large primary particles as well as aggregates, and that classifies the nanoparticles into powders with different mean sizes. The prototype design will be scalable to high flow rates of nanopowder and carrier gas, and can be located in-line with a synthesis reactor.

Structure and Response of Spherical Diffusion Flames

Sponsor: NASA

Having passed the Science Concepts Review, this project is officially designated as a space flight experiment. It capitalizes on the unique buoyancy-free environment offered by microgravity to acquire diffusion flame data of high fidelity for fundamental and canonical studies. The first objective is to interrogate the fidelity and comprehensiveness of the chemical kinetic mechanisms and transport sub-models used in the simulation of combustion phenomena, and consequently identify possible modifications. The second objective is to characterize and gain predictive capability on a number of important unit combustion processes including dynamics and extinction of diffusion flames, radiation heat transfer, flame pulsation, flame front stability, soot formation, and dynamics of rotating flames. The project encompasses experimentation, numerical computation, and analytical theory.

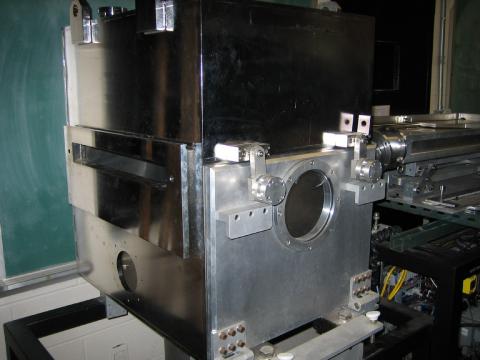

Aerodynamically-Enhanced Plasma Processing of Nano- Coatings/Powders/Energetics

Sponsor: Rutgers Academic Excellence Fund

An 80 kW DC arc plasma system provides the high temperatures needed (30,000 F) to processes ceramic materials and create ceramic coatings. The Sulzer-Metco 9MP system incorporates a computer controlled powder feeder so that process parameters can be accurately monitored. The plasma gun is fitted onto various reactors to process different materials.

An 1.5kW 40MHz RF inductively-coupled plasma reactor operating in a chamber is utilized for synthesis of metastable compounds by exploiting strategic aerodynamic geometries. The program integrates the synthesis/processing, in-situ laser-based diagnosis, and subsequent characterization of nanoparticle-based materials to optimize manufacturing of nanostructured coatings, powders, and energetics for specific applications and functions.

HVOF Processing of Nanostructured Materials

Collaborator: A&A Co. Inc.

High Velocity Oxy-Fuel (HVOF) technology is being developed to produce nanostructured powders, coatings, and preforms, using a HVOF torch as heat source and a solution precursor or aggregated powder as feed material.

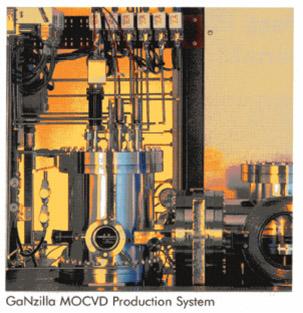

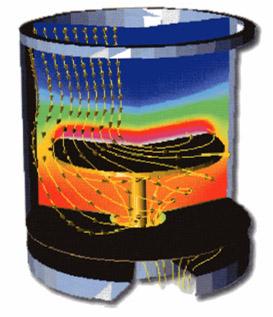

Flow and Species Diagnoses in MOCVD Processing of Large Band Gap Materials

Sponsor: Veeco Turbodisc, Emcore Corporation

This work involves in-situ diagnostics and modeling of CVD aerothermochemistry in AlGaN- and InGaAlP-based wafer (wide-band-gap materials) production.